TONYOUNG Plastic PackagingEPS、EPE、EPP、EPO

Professional packaging material manufacturer

- Home

- About

-

Column classification navigation

View more +About TONYOUNGOur company was founded in 1985 and is a professional manufacturer of packaging materials. Meanwhile, with the growth of the global information industry, our company's business performance has also been increasing year by year.

-

- Product

-

Product classification navigation

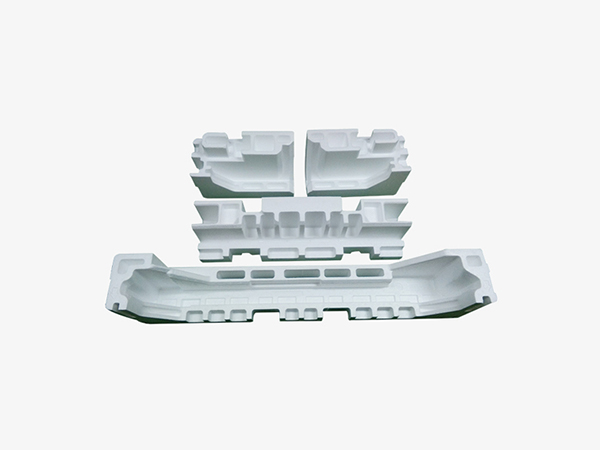

View more +Recommended products

-

- Case

- News

-

News classification navigation

View more +Hot News2025-01-17Dongyang EPP is the abbrevia...2025-01-17Dongyang EPS is polystyrene ...2025-01-17EPE, It refers to foamed pol...2025-01-17EPS packaging is very common...

-

- Contact

-

Column classification navigation

View more +Contact DongyangWelcome to the "Contact Us" page. Your visit is a sign of support for us, and we sincerely welcome your visit! Dongyang impresses customers with its excellent technology and sincere service.

-